MEGC

adjustable ipad stand, tablet stand holders。

MEGC

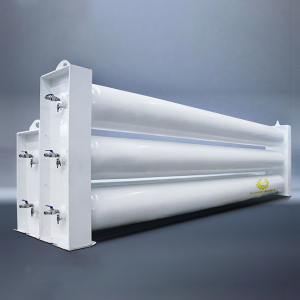

Electronica gas MEGC is used for multiple transporting electronic gas, such as SiF4, SF6, C2F6 and N2O. Multiple transporting includes road and sea transportation.

Product introduction

Electronica gas MEGC cylinder could be designed and manufactured with different code including DOT, ISO. We could always fulfil proposal with different working pressure, brand of valves & fittings based on customer's condition and requirement.

Form information

| Media | Tare Weight(Kg) | Working Pressure(Bar) | Total Water Capacity(Liter) | Moisture Level(ppm) | Roughness |

| N2O | 14000 | 180 | 13300 | Mini.≤1 | ≤0.8μm |

| BF3 | 16288 | 180 | 16640 | ≤2 | ≤0.8μm |

| VDF | 16288 | 180 | 16641 | ≤20 | |

| NF3 | 9723 | 166 | 17144 | Mini.≤1 | ≤0.25μm |

| SILANE | 16500 | 166 | 17144 | Mini.≤1 | ≤0.25μm |

| HCL | 12500/11500 | 138(DOT)/152(ISO) | 11110 | Mini.≤1 | ≤0.25μm |

Product description

Electronica gas MEGC is used for multiple transporting electronic gas, such as SiF4, SF6, C2F6 and N2O. Multiple transporting includes road and sea transportation.

Electronica gas MEGC will get IMDG, CSC certificate.

Electronica gas MEGC cylinder could be designed and manufactured with different code including DOT, ISO. We could always fulfil proposal with different working pressure, brand of valves & fittings based on customer's condition and requirement.

Our Electronica gas MEGC are already widely used for famous international gas company in world with cost-effective, &high performance feature.

Safety and efficiency are most important factors, they are widely used around world and enjoy high reputation

The feature of the product:

1. The product size is standard 40ft&20ft meeting IMDG, CSC.

2. The bursting discs are designed with each cylinder of Industrial Gas Container, that make the operation more safety under the emergency condition.

3. The advance manufacture technology and equipment, feasible quality insurance system;

4. Cylinder standard can be DOT or ISO, and also can be mixed DOT&ISO to make product world used.

5. Complete manifold adopts EP class pipe, CGA valves, and orbital welding process;

6. Helium leakage test rate reaches to 1*10-7 pa.m3/s;

7. Roughness: 0.2~0.8μm; Moisture level: 0.5~1ppm; Particle content(NVR): 50~100mg/m2.